Welcome at Aerosoldosen Limburg GmbH

We stand the pressure

ADL GmbH was founded in 2013.

JOINT VENTURE

We are a joint venture between the Massilly Group and Blechwarenfabrik Limburg GmbH. Both companies have decades of experience in the production of tinplate packaging. Our production was planned and established in the new facility of Blechwarenfabrik, which integrated all the requirements of the industry 4.0 standard and specialized in the manufacturing of 3-piece tinplate aerosol cans.

Aerosol Can

Product & Print Service

Our aerosol cans are high-performance products

PRODUCT & PRINT SERVICE

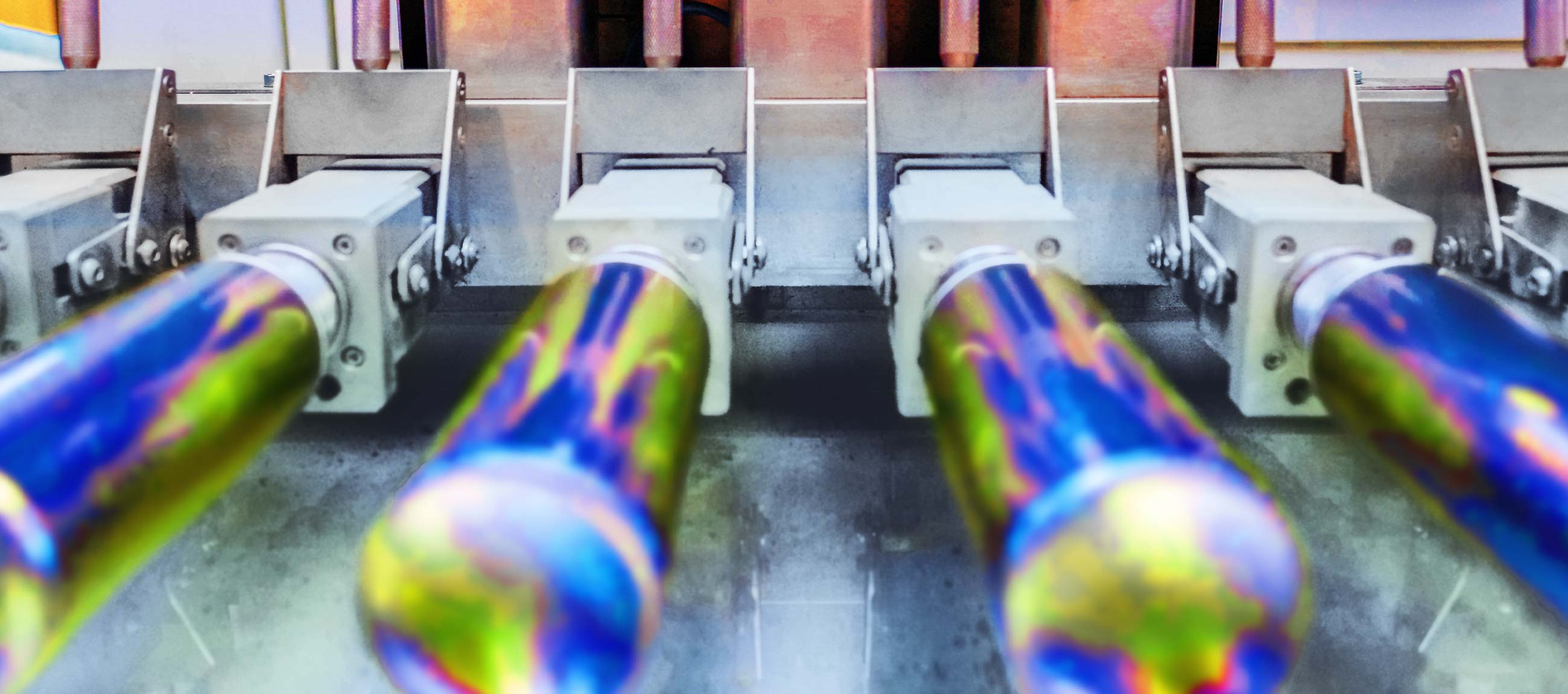

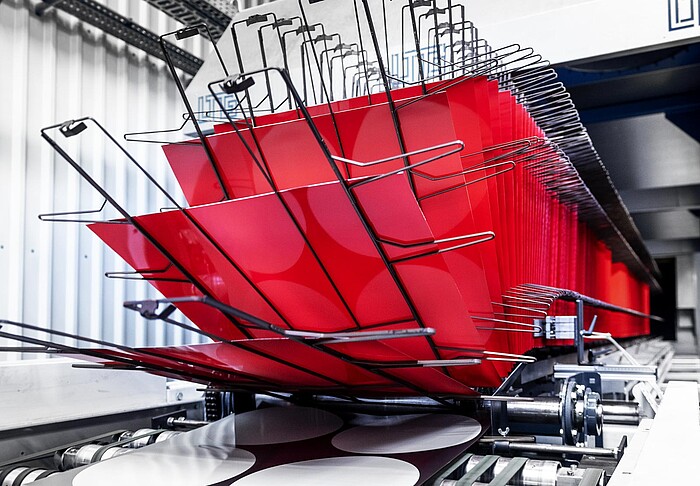

Highest requirements for dimensional accuracy and pressure safety meet large output quantities. To achieve this, only new machines from leading European manufacturers were used for the ADL.

ADL is the subsidiary of the Massilly Group and Blechwarenfabrik Limburg GmbH. Two strong partners with many years of experience in the production of tinplate packaging.

Massilly Group supports ADL with its know-how in aerosol manufacturing, supplies the components and complements the product portfolio. On the other hand, Blechwarenfabrik provides technical support and logistics. Finishing is carried out on a modern UV-printing machine.

Both, Euro-scale colours, as well as special colours are possible.

PRODUCT DATA (Product Specifications)

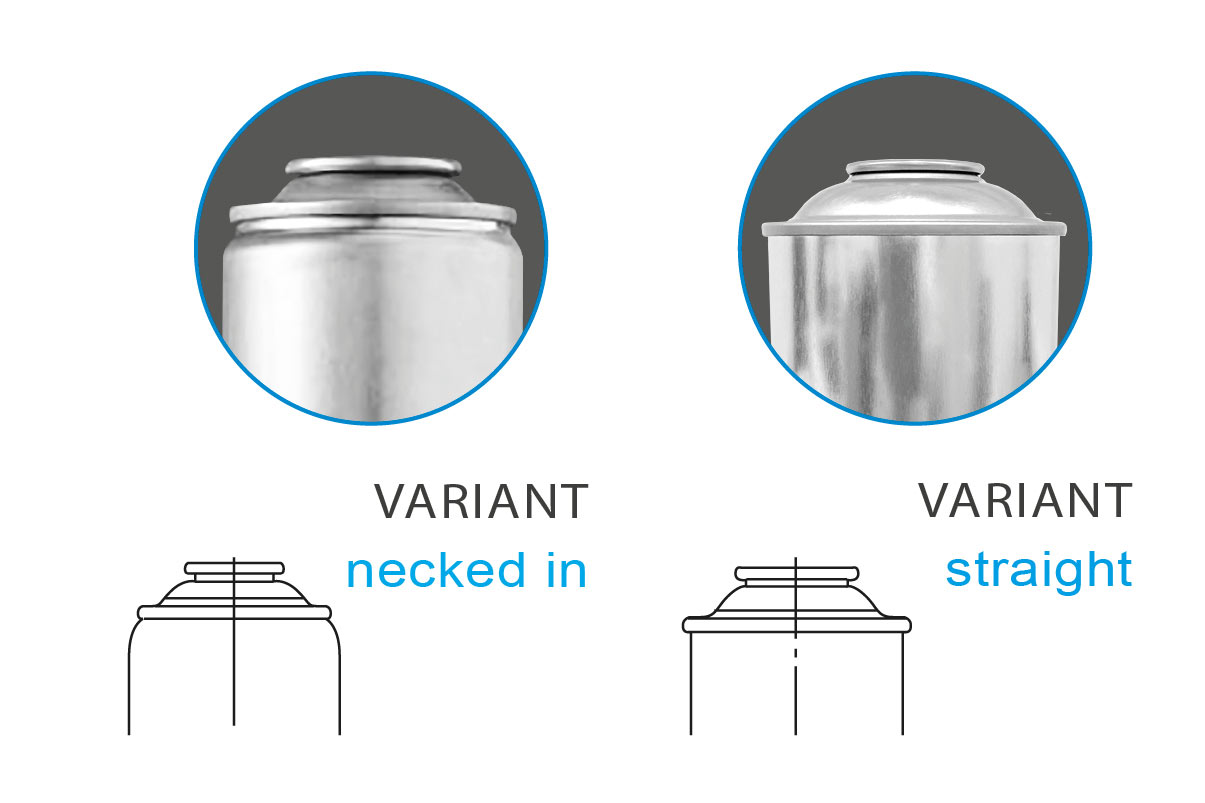

Deliverable sizes and versions

| Filling volume (ml) | Cans volume (ml) | Height (mm) | Variant | |

|---|---|---|---|---|

Ø 52 mm | 150 | 210 | 105 | necked in |

| 200 | 270 | 132 | necked in | |

| 250 | 335 | 161 | necked in | |

| 300 | 405 | 195 | necked in | |

| 400 | 520 | 244 | necked in | |

Ø 57 mm | 200 | 270 | 110 | necked in |

| 250 | 335 | 136 | necked in | |

| 300 | 405 | 164 | necked in | |

| 400 | 520 | 207 | necked in | |

| 500 | 650 | 257 | necked in | |

Ø 65 mm | 250 | 335 | 104 | necked in + straight |

| 300 | 405 | 122 | necked in + straight | |

| 400 | 520 | 157 | necked in + straight | |

| 500 | 650 | 195 | necked in + straight | |

| 600 | 800 | 240 | necked in + straight | |

| 750 | 1000 | 300 | necked in + straight |

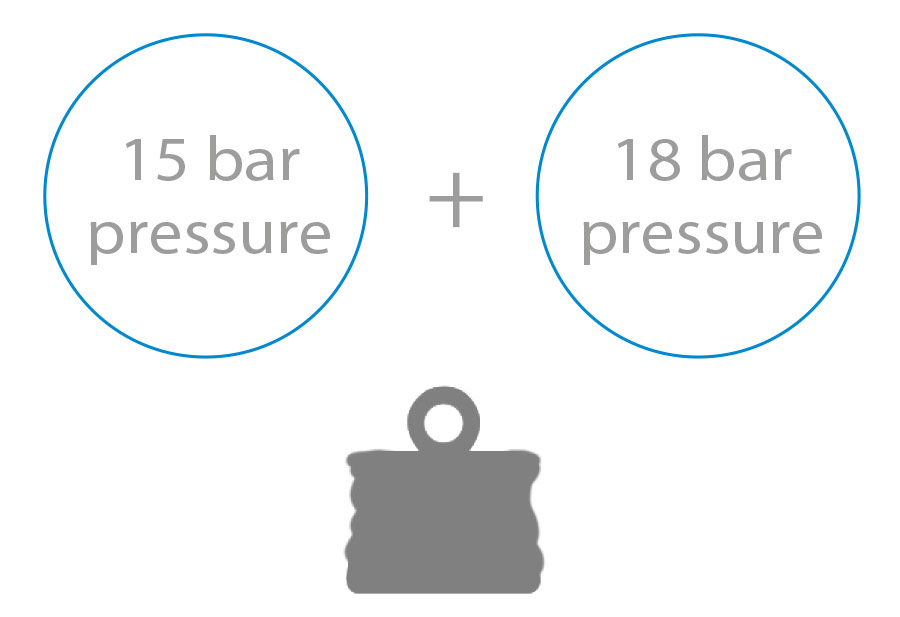

All cans are deliverable in 15 or 18 bar. Further sizes and variations on request.

Aerofoka

Product & Print Service

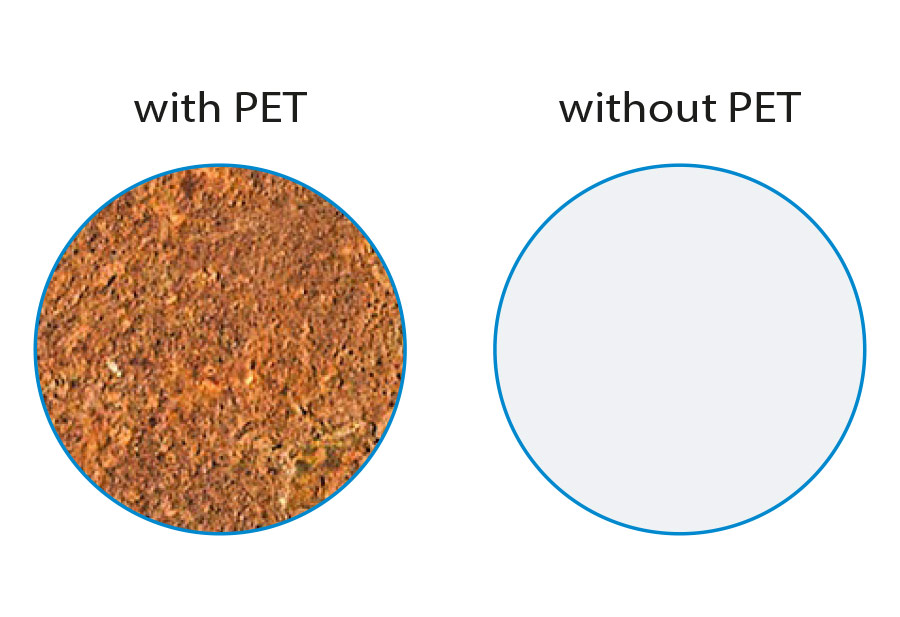

PET-film coating inside

AEROFOKA

Film lamination is the inner coating of tinplate packaging with a PET film. In the further development of the classic organic inner coating using varnishes, an inner surface completely covered with PET is created with the lamination.

Advantages of the foil coating inside:

- CHEMICAL RESISTANCE

- HIGH ABRASION RESISTANCE

- BPA NON-INTENT*

- NON-POROUS

- ELASTICITY

- ESPECIALLY STRONG FOR THE AREA OF WATER-BASED FILLING GOODS.

* A lacquer/adhesive without BPA as a starting material is referred to as BPA-NI (BPA non-intent).

Aerosol cans

Quality

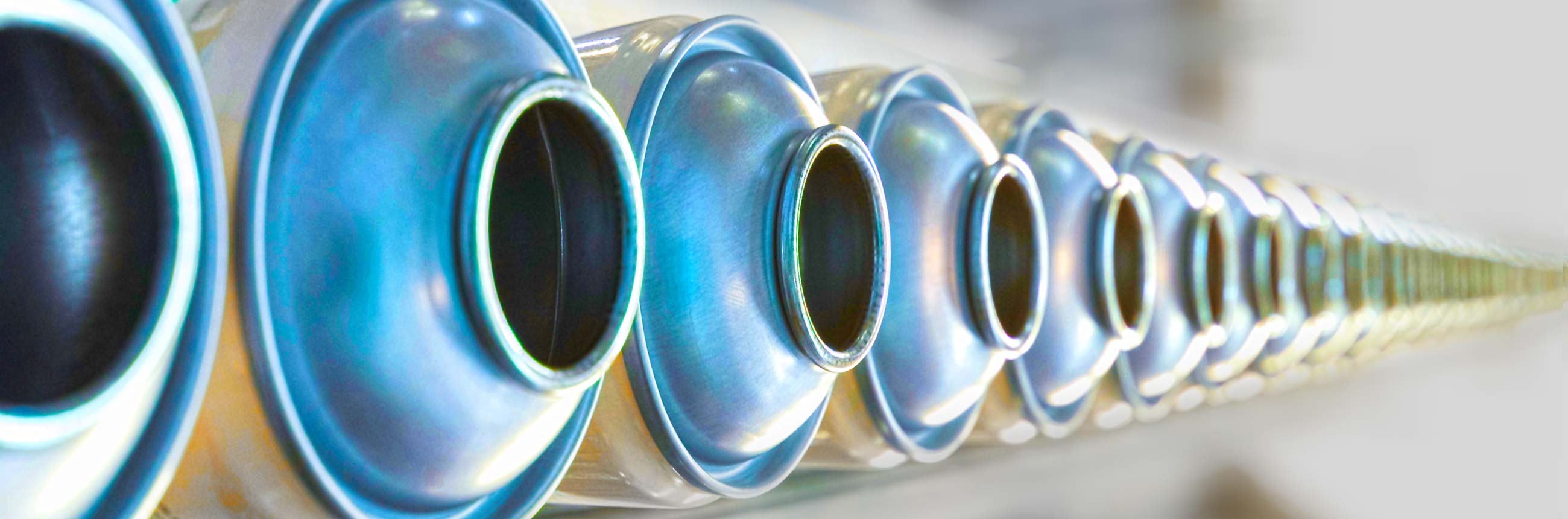

All cans are tested for leaks in-line with a high-pressure tester.

QUALITY & CERTIFICATION

In addition, containers are constantly taken from production and checked for micro-leaks in a waterbath. Cans are checked for dimensional accuracy at regular intervals. All measuring devices are electronically connected, the test data is recorded automatically. The fold check is carried out using a high-resolution camera and automatic pattern recognition. To ensure pressure safety, the deformation and bursting pressure is determined by a destructive test.

All of these measures ensure the consistent quality of our aerosol cans.

Aerosol cans

Product gallery

Four production sites for aerosols

MASSILLY IBERICA GRUMETAL (Zaragoza)

MASSILLY UK (Swansea)

MASSILLY RUSSIA LINAR (Nevinnomyssk)

ADL (Limburg)

Tinplate Packaging

Company & Partners

Aerosol cans

Downloads

Aerosol cans

Contact

ADL GmbH

Anna-Ohl-Straße 1

D-65555 Limburg

Phone: +49 (0) 6431 299-303

Fax: +49 (0) 6431 299-8303

E-Mail: info(at)aerosol-limburg.de

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/f/3/csm_aerosol-dosen-limburg-gmbh_gallery_2_0895ca113d.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/2/4/csm_aerosol-dosen-limburg-gmbh_gallery_3_6bb36992d1.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/4/1/csm_aerosol-dosen-limburg-gmbh_gallery_4_a2e1bc30c7.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/f/9/csm_aerosol-dosen-limburg-gmbh_gallery_5_7923c48691.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/d/0/csm_aerosol-dosen-limburg-gmbh_gallery_6_f1b9c24b4c.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/6/a/csm_aerosol-dosen-limburg-gmbh_gallery_7_614d78c102.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/0/0/csm_aerosol-dosen-limburg-gmbh_gallery_9_c8d9fcf631.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/e/c/csm_aerosol-dosen-limburg-gmbh_gallery_10_adddadb3d3.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/5/4/csm_aerosol-dosen-limburg-gmbh_gallery_11_82f8cb2aef.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/7/2/csm_aerosol-dosen-limburg-gmbh_gallery_12_5a9927a959.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/6/1/csm_aerosol-dosen-limburg-gmbh_gallery_13_44df120e2a.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/c/d/csm_aerosol-dosen-limburg-gmbh_gallery_15_85cf9d0e61.jpg)

![[Translate to Englisch:] Aerosoldosen Limburg GmbH Impression [Translate to Englisch:] Aerosoldosen Limburg GmbH Impression](/fileadmin/_processed_/9/9/csm_aerosol-dosen-limburg-gmbh_gallery_16_1b62a0b602.jpg)